MyDro 150, 850

The Next Generation of Wireless Real-Time Alarm, Monitoring, and Remote Control

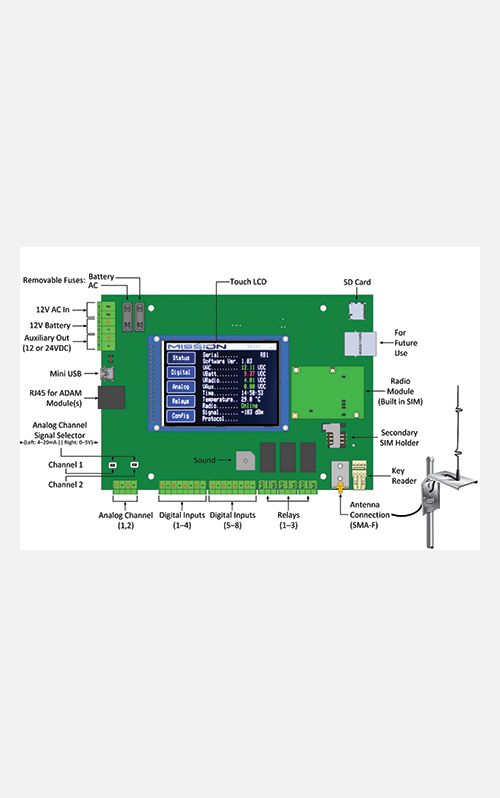

The MyDro 150 and 850 have all of the functionality of their predecessors, the M110 and M800, with an added onboard interactive display and enhanced electronics. Each remote terminal unit (RTU) includes the necessary hardware for a standard installation—such as a cellular radio, enclosure, backup battery, transformer, and an antenna with a cable and mounting hardware. Purpose-built RTUs simplify and speed installation. There is no programming required, and RTUs are self-enrolling.

View the comparison chart here.

Features:

Reliable Wireless Communications

RTUs feature a game-changing radio with an embedded SIM that supports multiple carriers (AT&T, T-Mobile, and Verizon) as well as a removable SIM for future options such as FirstNet. That means access to multiple carriers is automatic with no need for a site visit to change a SIM. There are no radios to license, nor cellular contracts to set up.

Real-Time Alarms Delivered To All Devices

Real-time alarms are delivered via phone call, text message, email, fax, page, and even to an existing HMI software via an OPC data link. Each alarm is logged with a timestamp for tracking and reporting. The alarm call-out schedule setup is easy, flexible, and intuitive, which allows it to be as simple or sophisticated as users require.

Managed Service—the Complete Package

The Mission system includes cellular data service, data storage, alarm call-outs, reports, and technical support that is on call 24-7-365. The highly reliable, turnkey system offers more features at a lower cost than an in-house setup. No engineering or programming is required and there are no networks to maintain.

View data and reports using the Mission 123SCADA web portal, accessible on any web-enabled device. 123SCADA is the Mission user interface designed with the look and feel of industry-standard HMI SCADA that many new features as well as a legacy user mode. Tabular and graphical reports can be used for compliance reporting and comparative studies. As always, system enhancements are included at no cost and are immediately available.

MyDro 150 RTUs

Real-Time Alarms with Hourly Summaries

The MyDro 150 summarizes analog data, RTU status, pump run times, and pump starts hourly. All alarm data is reported in real-time. Simultaneous pump runtimes can be reported when two pumps run.

MyDro 850 RTUs

Real-Time Alarms and Streaming Data

The MyDro 850 reports pump starts and stops in real-time. Analog values are reported every two minutes or on a 5% change. Volumetric flow calculations can utilize this information along with sump volume (as determined by an analog level sensor or fixed entries) to calculate hourly volumetric flows.

Remote Control

System capabilities may be expanded with optional remote control interfaces, such as automatically controlling offsite wells, tanks, gates, chlorine dosers, variable frequency drives (VFDs), and more, with optional remote control interfaces such as the Tank and Well Control Package, Digital Interconnect, and Analog Interconnect.

Expandable Input/Output

Expand MyDro 850 possibilities with MyDro Expansion Modules. The MyDro supports multiple modules simultaneously. Each type provides the following to onboard capabilities:

• Safe Module Plus—wet well module that adds four pulse channels

• Analog Input—adds seven channels for a total of nine

• Analog Output—adds up to four channels

• Digital Input—adds eight channels for a total of 16

• Digital Relay Output—adds six channels and up to two modules for a total of nine channels