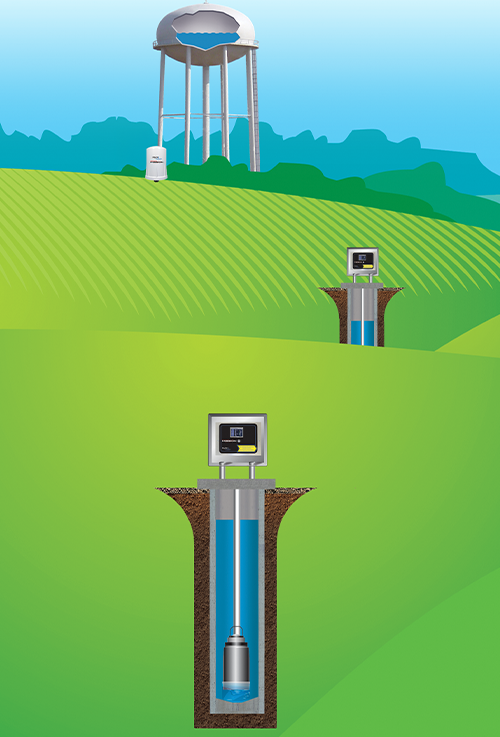

Tank and Well

Remote Control for Water Systems

The Mission Tank and Well System maintains the water level in a storage tank by automatically commanding remote well or booster pumps to turn on and off. The system relies on standard Mission remote terminal units (RTUs) and a transducer to monitor the tank level. There are no private radio networks, computers or programmable logic controllers (PLCs) to maintain. It is low cost and easy to set up.

How it Works

The MyDro RTU at the water tank continuously monitors level or pressure. That signal gets transmitted through secure cellular networks to our servers. The RTU may be connected to other equipment such as chlorine monitors or digital alarms. Depending on the RTU chosen, it can be line powered (MyDro 850) or battery powered (MyDro 50).

When the tank level is outside the user configured level thresholds, a command is automatically sent to energize pumps or valves and refill the tank. The Tank and Well software supports up to five outputs (pumps, valves, etc.).

Real–time notifications and reports inform operators of high pump starts, excessive pump runtimes, AC failure, low battery, and more. The 123SCADA web portal securely allows an operator with appropriate access permission to adjust the pump on/off trigger levels and other settings. Current level readings are available via trending graphs and reports on desktop computers and through the 123SCADA app on smart phones and tablets.

Optimization and Money Saving Features

The software includes a virtual pump alternator feature which cycles through each well pump connected to a Tank and Well system. It can be set up to evenly distribute pump runtimes across all wells.

Maximum runtimes can be set for each pump, and the system will alternate to the next pump once the maximum runtime is reached. This reduces the risk of damaging the water table by over pumping. An off–peak force fill feature is available to save money by filling a tank when electricity rates are lower than peak hour rates.

Behind–the–scenes business logic is available to notify of abnormal situations that can affect system performance. For example, a “call–to–run fail–to–run” alarm notification can be dispatched by the system if the well pump does not run when commanded. This could happen if the well is without AC power, an operator has locked the pump out locally (typically with the hand–off–auto (HOA) switch), or the pump requires service (motor inoperable). More information is available in our document Best Practices for Remote Control, which can be found on the 123SCADA web portal in the Start Menu > Help > Documents view.