M110

Wireless Real-Time Alarm System

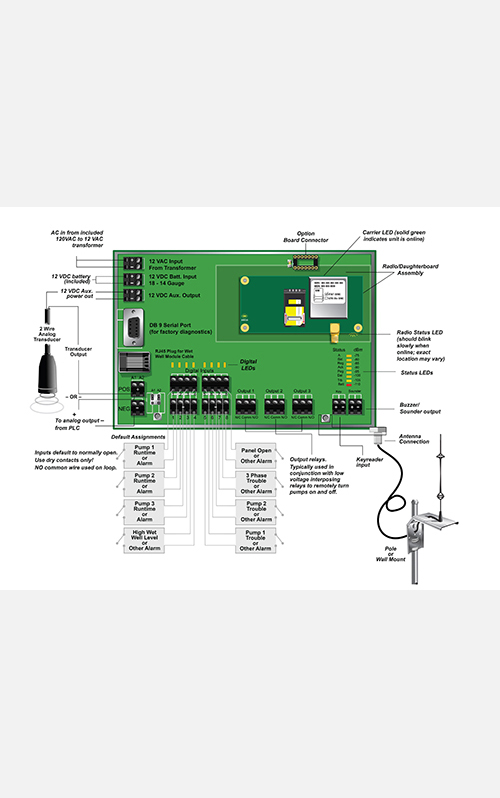

The M110 is the lowest-cost remote terminal unit (RTU) and is appropriate for the typical sewer lift station. Purpose-built RTUs speed and simplify installation. Each M110 is a complete wireless monitoring system. It includes the necessary hardware for installation, including:

- Cellular radio

- Enclosure

- Backup battery

- Transformer

- Antenna with cable

- Mounting hardware

Customers can upgrade to the latest capabilities with the MyDro 150. This RTU includes all of the M110 functionality and adds an LCD touch screen display and advanced electronics. If users need analog trending data and real-time pump state changes for master lift stations, the M800 or MyDro 850 systems are ready for the job.

View the comparison chart here.

Features:

Reliable Wireless Communications

RTUs operate on current generation (2G, 3G, and 4G) cellular radios for dependable data transmissions. Mission maintains direct relationships with the largest cellular carriers in the U.S. and Canada to ensure the best service possible. There are no radios to program, no cellular contracts to set up, and no radio licenses to purchase and maintain.

Reactive Alarms and Proactive Alerts

Real-time alarms are dispatched based on a customized call-out schedule. Alerts proactively notify users of possible issues like excessive pump starts or runtimes.

Mission-Managed Service

Mission-managed SCADA is a turnkey system delivered through a Software as a Service (SaaS) model that enables customers to gain complete system monitoring. Mission provides and maintains everything users need to drive their systems.

Robust and Secure Web Portal

The state-of-the art 123SCADA web portal automatically adapts to large monitors, tablets, and smartphones, with a dashboard window conveniently displaying all necessary information.

To learn more about Mission-managed services, download the Managed SCADA brochure.